The beginning of all claims is the demand for more.

SOMI is a specialist in the field of conception and realization of individual cleaning and sterile packaging solutions. SOMI cleans, assembles and packages components for customers in the dental and medical technology, aerospace and electronics sectors.

SOMI is the competent service provider for customers in the fields of dental and medical technology, aerospace and electronics.

The cleaning, assembly and packaging of your products takes place in our class 7 clean rooms.

We offer customized logistics for your products – from controlled storage in sterile warehouses to worldwide shipping.

Claim

Claim

Trust

Trust

Long-Term

Long-Term

Uniqueness

Uniqueness

Fancy someting new

Fancy someting new

Climate

Climate

SOMI is your partner for special tasks and specific applications. We stand for first-class quality, customized problem solutions, constant readiness to deliver and friendly service.

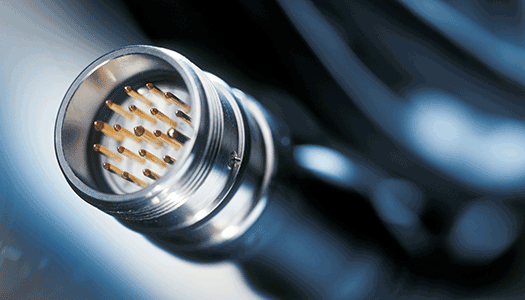

Sigrist stands for innovative solutions that revolutionize the boundaries of electroplating.

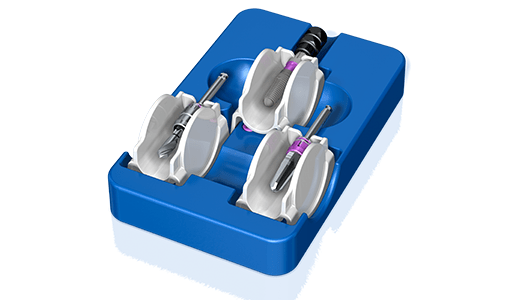

LOGON presents a comprehensively modernized overall concept for dental implantology.